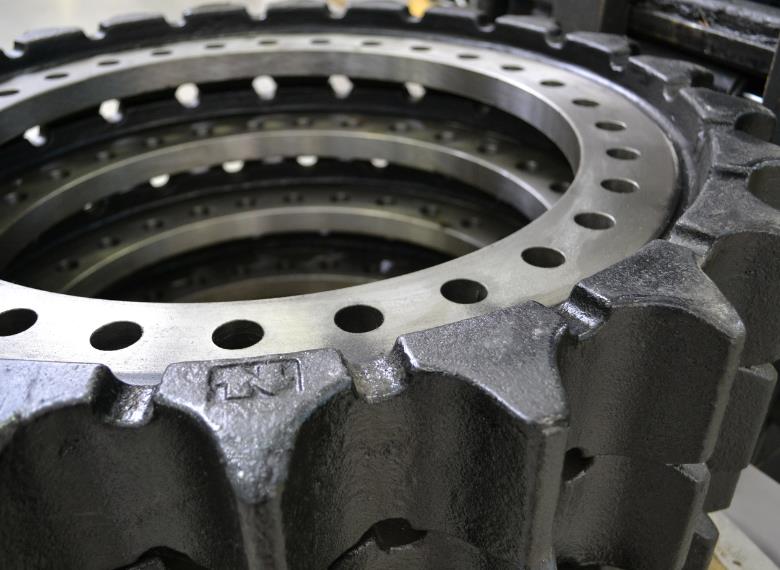

At the core of every job site, amidst the sound of engines and the dust being kicked up, there is an element working tirelessly beneath the machine, often forgotten but fundamental to every single movement. It’s not the boom, it’s not the cab. It’s the undercarriage, and within it, the sprocket is the true star.

This is not a simple gear. It’s the point of contact between the engine’s force and the ground, the crucial link that transforms power into traction, allowing your machine to tackle climbs, rough terrain, and heavy loads. Without a reliable sprocket, the machine stops.

The Key Role and Technical Characteristics

The sprocket, generally located at the rear of the undercarriage, is a critical element of the track system. Unlike idler wheels, which guide the track at the front, the sprocket is the only part that engages with the track to move it forward. To withstand the enormous torsional stresses and constant wear, it requires the highest quality materials and special treatments.

High-quality sprockets are produced using either casting or forging processes, depending on the specific application, and are heat-treated to ensure superior surface hardness across the entire tooth profile. This induction hardening treatment significantly increases wear resistance, extending the component’s useful life and preventing premature failure.

A Range Adaptable to Every Need

Our partner, Berco, is a specialized and leading manufacturer in the industry, with an offering that meets the needs of machines ranging from 1 to 330 tons. The company’s experience has led to the development of specific solutions for different applications:

- Sprockets for Bulldozers: Often featuring a bolt-on segment design, they allow for quicker and easier maintenance, as there is no need to remove the entire track for replacement.

- Sprockets for Mining Excavators: Designed with an odd number of teeth, they offer greater resistance to vertical loads and a special profile that facilitates mud discharge, preventing buildup and ensuring optimal performance even in extreme conditions.

Whether the machine is intended for heavy-duty work on a construction site or in a quarry, or if it operates on difficult terrain, the right sprocket is essential to prevent costly downtime and ensure that work proceeds smoothly.

Sprockets are available in both the Berco and Sampierana lines.

Choosing Quality: The Partnership with Berco

The choice of a quality replacement part is not only a matter of durability but also of safety and operational efficiency. This is where the importance of relying on a partner like Sampierana UC Spare Parts becomes clear. Thanks to our long and consolidated partnership with Berco, we are able to provide you with components that meet all the quality standards described above. We offer the necessary support and expertise to help you choose the perfect sprocket for your machines.