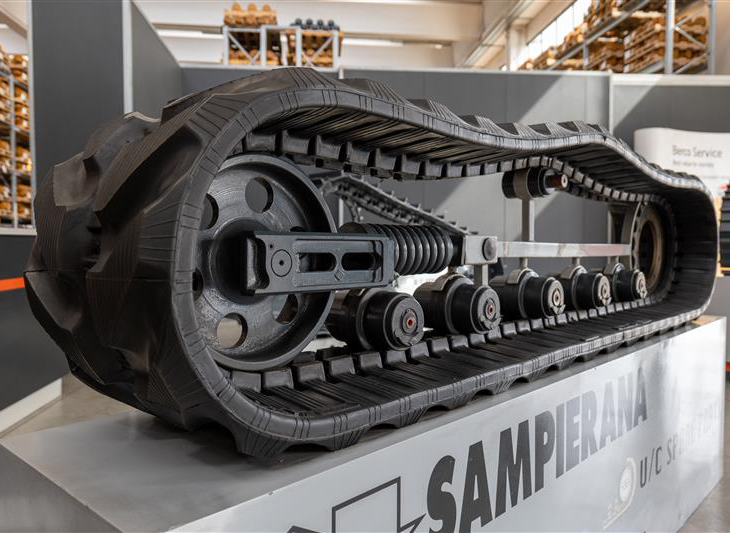

Every operator knows that the secret to a productive earthmoving machine lies in the reliability of its undercarriage. While the track chain and rollers attract attention, there is an essential component that works tirelessly to protect them from wear and damage: the Idler Group, which houses the Idler Wheel.

Ecco la traduzione del primo blocco: “Every operator knows that the secret to a productive earthmoving machine lies in the reliability of its undercarriage. While the track chain and rollers attract attention, there is an essential component that works tirelessly to protect them from wear and damage: the Track Adjuster Assembly (or Idler Group), which houses the Idler Wheel. The Track Adjuster Assembly is not a luxury, but a fundamental safety mechanism. Its function is twofold and vital: to guide the track to prevent derailment and to absorb shocks to protect the chassis from overloads. Without an efficient tensioning system, the entire service life of your track will be drastically reduced.

The Three Executive Roles of the Tensioning System

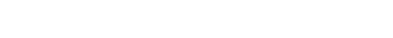

When we talk about the Track Adjuster Assembly, we are talking about an orchestra of components that work together. The effectiveness of a Berco system lies in the synergy of its key elements

- Guidance and Alignment (The Idler Wheel): The idler wheel directs the track chain, ensuring its correct alignment. An optimized profile reduces friction and dirt accumulation, ensuring smooth rotation

- Impact Protection (The Spring Assembly): A preloaded spring acts as the true shock absorber for the tracked machine. When the idler wheel encounters a rock or an obstacle, it is the spring that compresses, absorbing the shock and preventing the destructive force from spreading inside the frame and to the other undercarriage components.

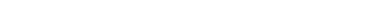

- Tension Adjustment (The Hydraulic Adjuster Assembly): Using a grease cylinder, the operator can adjust the track tension. By injecting grease, the system pushes the idler wheel forward; by releasing grease, the tension is reduced. This allows the correct degree of tension to be maintained, which is crucial for preventing abnormal stretch and premature wear of pins and bushings.

Why Berco Quality is Non-Negotiable

The constant pressure and exposure to mud, water, and dust make the Track Adjuster Assembly extremely vulnerable. A low-quality component fails first at the sealing system (seals), allowing contaminants to destroy the bearings and rendering the hydraulic adjustment ineffective.

This is why choosing Berco quality is an essential investment. Their components are designed with:

- Superior Sealing Systems: They protect the internal mechanism hermetically, even in the most aggressive environments.

- Advanced Metallurgy: Heat-treated steel ensures that both the idler body and the adjuster rod maintain structural integrity under extreme loads and abrasion.

Choose the Safety of the Complete System with Sampierana

Don’t just replace a part—invest in a complete protection system. Sampierana UC Spare Parts, in partnership with Berco, offers you Track Adjuster Assemblies that are synonymous with operational longevity and maximum safety.

We guarantee access to a complete and technically advanced supply, ensuring that the invisible shock absorber of your undercarriage always performs perfectly.